I will never forget the cinematic in Knights of the Old Republic when Darth Revan takes off his mask. What an EPIC moment! That scene will forever be etched in my mind as the greatest plot twist in video game history.

When the story of Revan was later continued with the release of Drew Kapryshyn's novel Revan and Bioware's new Star Wars: the Old Republic, I knew I couldn't put off tackling the mask any longer!

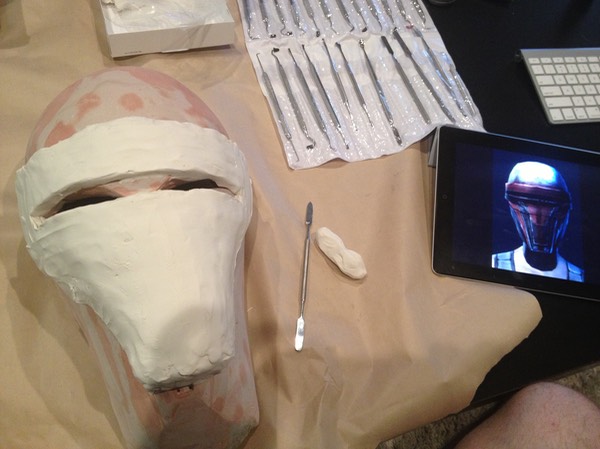

To start, I used my trusty old V1 Sith Acolyte Bondo Mold to use as a base, and used Sculpey to create a rough shape of the face.

Realizing it would be easier to tackle the visor later, I filled this in, and continued to work on smoothing out the surface.

Realizing it would be easier to tackle the visor later, I filled this in, and continued to work on smoothing out the surface.

Next, I threw this onto a baking tray and put the whole thing in the oven on 275F for about 70 minutes. While putting Sculpey in the oven is quite safe (and is exactly how you're supposed to cure it), in retrospect, I would NOT recommend putting anything Bondo in the oven. It stinks to high heaven and is actually quite toxic. I did it once, and will never do it again!

Next, I threw this onto a baking tray and put the whole thing in the oven on 275F for about 70 minutes. While putting Sculpey in the oven is quite safe (and is exactly how you're supposed to cure it), in retrospect, I would NOT recommend putting anything Bondo in the oven. It stinks to high heaven and is actually quite toxic. I did it once, and will never do it again!

Anyway, once the sculpt baked, I used an electric sander to smooth everything out.

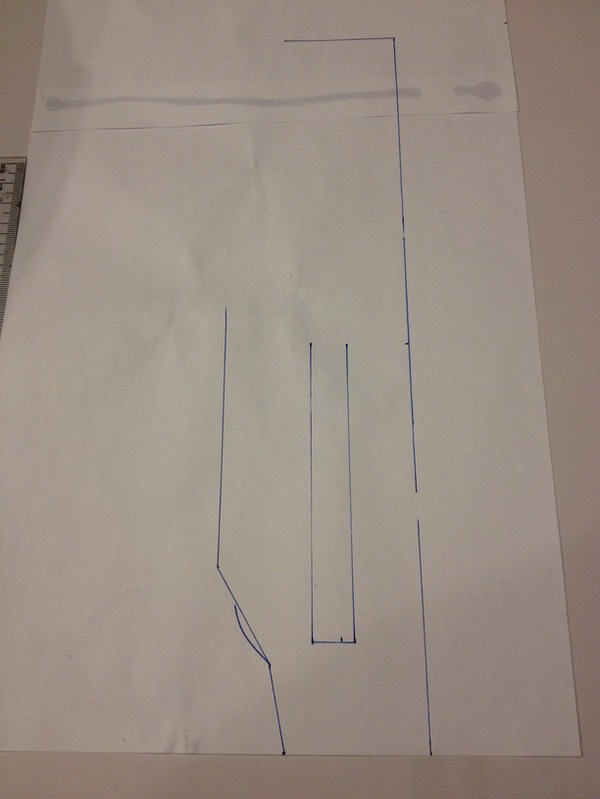

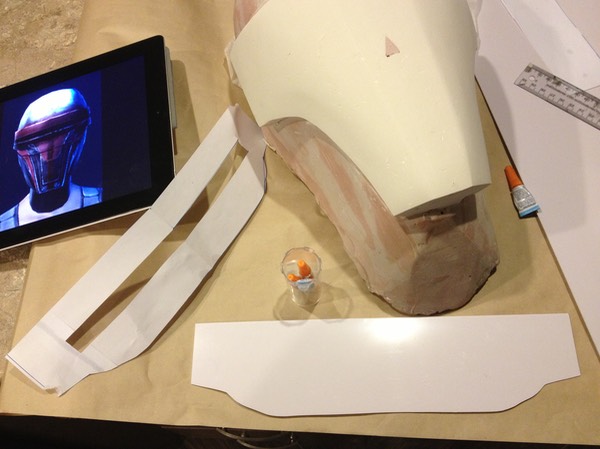

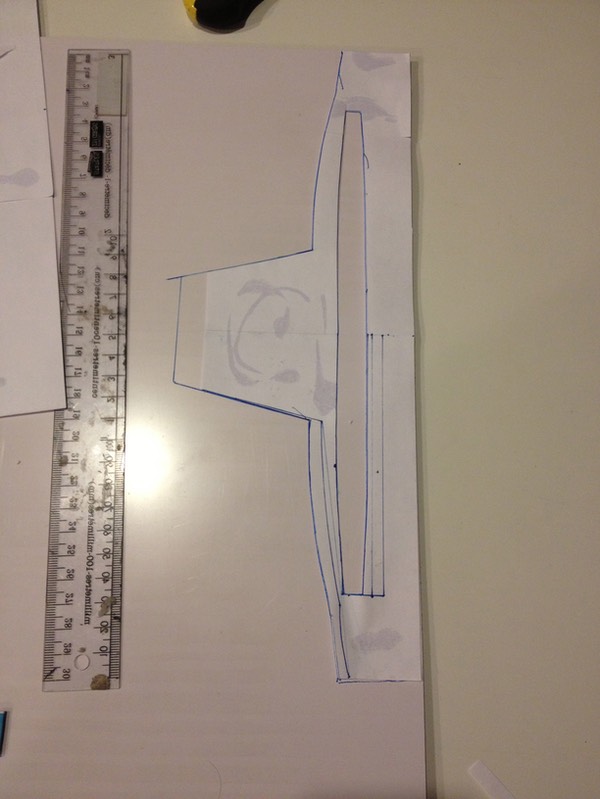

As Revan's mask looks to be made of layers, I decided to use some spare ABS sheets I had lying around to create the features. To make things easy, for each layer of detailing, I took a long sheet of paper, folded it in half, and drew half the design on it.

As Revan's mask looks to be made of layers, I decided to use some spare ABS sheets I had lying around to create the features. To make things easy, for each layer of detailing, I took a long sheet of paper, folded it in half, and drew half the design on it.

I then cut the design out, unfolded the paper, and got a perfectly symmetrical cutout which I then traced onto a sheet of .06 ABS, and cut out with scissors.

I then cut the design out, unfolded the paper, and got a perfectly symmetrical cutout which I then traced onto a sheet of .06 ABS, and cut out with scissors.

I then glued the first layer onto the cured Sculpey using superglue (which bonds really well to it, by the way), and proceeded to do the same fold-draw-cut-trace method with subsequent layers of the features.

I then glued the first layer onto the cured Sculpey using superglue (which bonds really well to it, by the way), and proceeded to do the same fold-draw-cut-trace method with subsequent layers of the features.

Next I needed to do the two little speakers (or whatever) at the bottom of the mask. I rolled up some sculpey, cured it with a heat gun, then cut two small pieces at an angle, and superglued two snap button (male ends) to make the speakers (or whatever).

Next I needed to do the two little speakers (or whatever) at the bottom of the mask. I rolled up some sculpey, cured it with a heat gun, then cut two small pieces at an angle, and superglued two snap button (male ends) to make the speakers (or whatever).

(At this point, the snap-button assembly had to be at an angle as in the above photo in order to face straight ahead on the curved mask surface. This will actually prove to be a needless set of steps when later in the process I end up deciding to change the length and shape of the mouth/chin area).

(At this point, the snap-button assembly had to be at an angle as in the above photo in order to face straight ahead on the curved mask surface. This will actually prove to be a needless set of steps when later in the process I end up deciding to change the length and shape of the mouth/chin area).

After cutting out more plastic pieces and supergluing them on, I ended up with this.

Next, I applied some Bondo to fill in the transitions, sanding it down to create some smooth Bondo goodness.

Next, I applied some Bondo to fill in the transitions, sanding it down to create some smooth Bondo goodness.

Next, I sprayed the whole thing with mold release, and over the course of 16 hours used two coats of Rebound 25 (also discussed here) thickened with Thi-Vex to make the rubber mold.

Next, I sprayed the whole thing with mold release, and over the course of 16 hours used two coats of Rebound 25 (also discussed here) thickened with Thi-Vex to make the rubber mold.

And finally, the first cast.

And finally, the first cast.

At this point I realized two things: 1) the mask was a tad too long, and 2) the front chin section was curved way too much compared to the reference photos. I could have left it as is, but no: it has to be perfect!

At this point I realized two things: 1) the mask was a tad too long, and 2) the front chin section was curved way too much compared to the reference photos. I could have left it as is, but no: it has to be perfect!

I cut off the chin, shortening the mask by about an inch. (I also cut out the eye slit just to see what it would look like, though I should have left this untouched for now). I used a little bench belt sander I just bought on clearance for $80 to shorten the bottom trapezoid, careful not to chew too far into the surrounding area.

You may notice the curve of the cranium is slightly different from that of the Bondo Mold. This is because I used Smooth Cast 325 resin for this casting, which has a tendency to remain quite rubbery after demolding. This allowed me reshape the curvature of the forehead simply by bending and twisting the resin, thereby letting it harden to correct shape. I used SC 325 for this very purpose: it is a lot easier/cleaner/healthier to bend rubbery plastic into shape than it is to sand a pound of Bondo off a mold to reach the desired shape (which often requires adding more Bondo, more sanding, more Bondo, rinse and repeat).

You may notice the curve of the cranium is slightly different from that of the Bondo Mold. This is because I used Smooth Cast 325 resin for this casting, which has a tendency to remain quite rubbery after demolding. This allowed me reshape the curvature of the forehead simply by bending and twisting the resin, thereby letting it harden to correct shape. I used SC 325 for this very purpose: it is a lot easier/cleaner/healthier to bend rubbery plastic into shape than it is to sand a pound of Bondo off a mold to reach the desired shape (which often requires adding more Bondo, more sanding, more Bondo, rinse and repeat).

Next, I dremelled some more lines on the mask, filled in a few trouble spots with Bondo, and used a heat gun to curve out (or flatten) the bottom of the face. I then used a fresh pair of snap-buttons to add the speaker (or whatever) detail.

I then used a progression of 120, 220, 400, 800, and 1000 grit sandpaper to smooth down the surface to get the thing ready for rubber moulding (again *sigh*). I used a piece of ABS to cover the eye slit from the inside, slapped the mask back on the Bondo mold (after busting off the original Sculpey-ABS master), and used a bit of Sculpey to fill in the gaps between the Bondo mold and the mask. I left the Sculpey uncured.

I then used a progression of 120, 220, 400, 800, and 1000 grit sandpaper to smooth down the surface to get the thing ready for rubber moulding (again *sigh*). I used a piece of ABS to cover the eye slit from the inside, slapped the mask back on the Bondo mold (after busting off the original Sculpey-ABS master), and used a bit of Sculpey to fill in the gaps between the Bondo mold and the mask. I left the Sculpey uncured.

Once again, using two separate coats of Rebound 25 thickened with Thi-Vex, I created a new rubber mold; using PlastiPaste 1, I then created the mother mold.

Now I decided to try something I haven't successfully done before: cold casting.

Now I decided to try something I haven't successfully done before: cold casting.

Cold casting is a process by which a fine metal powder is mixed in with resin, which upon curing, can be buffed and polished to a real metal look. I've seen it done before, and the effect is truly amazing - if done right, you cannot tell it's not solid metal!

So, I acquired 5 pounds of 325 mesh aluminum powder and set to work! Using Smooth Cast 65D as the main medium, I measured out equal parts of part A and part B to about 3 parts of aluminum powder, and mixed it all in a red solo cup.

NOTE: though the pictures show only 1 part powder, after snapping the photos, I quickly added two more scoops. I read somewhere that you can add as many as 10 parts of powder, though I didn't want to go that far. Anyway, I didn't have time to take a photo of this as I had very little time left to mix (as technically, the powder should be mixed into part B first, before adding part A).

Also, A breath mask is crucial at this point, as the aluminum powder is extremely fine and can be easily inhaled.

I dumped this mixture into the mold, smushed it around with my finger to drive out any bubbles, and slush cast the first layer. Since the mask only needs to look metal on the outside, the two subsequent layers were done using 65D without adding aluminum.

I dumped this mixture into the mold, smushed it around with my finger to drive out any bubbles, and slush cast the first layer. Since the mask only needs to look metal on the outside, the two subsequent layers were done using 65D without adding aluminum.

The final cast came out quite nice.

Next, some trimming and sanding, and buffing using #000 and #0000 steel wool, and the mask began to shine! Really happy with the way it turned out!

Next, some trimming and sanding, and buffing using #000 and #0000 steel wool, and the mask began to shine! Really happy with the way it turned out!

Since the photo doesn't really do it justice, here is a video of the results.

Since the photo doesn't really do it justice, here is a video of the results.

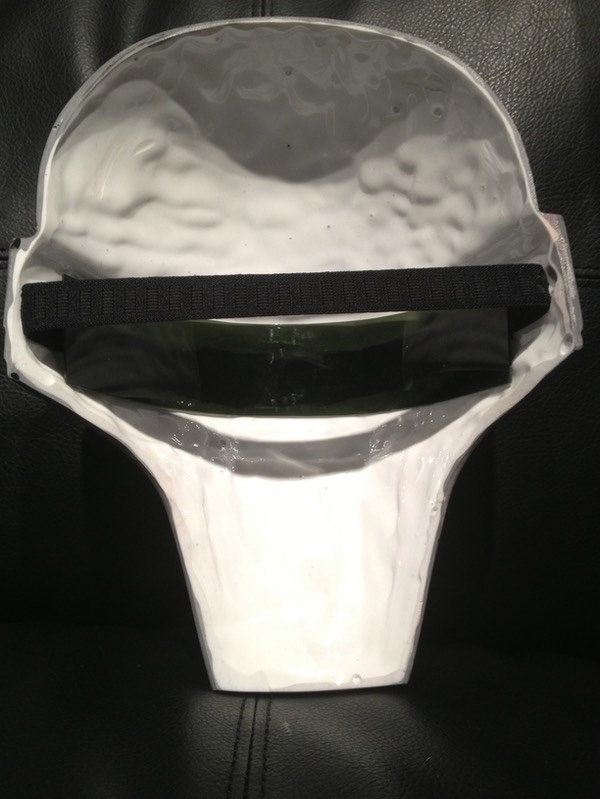

The cast was finally ready for painting and visor installation. (To create the visor slit window, I used a welder's face shield, which I cut and installed into the mask using velcro for easy removal and cleaning.)

Lastly, I used some #000 and #0000 steel wool to buff the forehead, Testors paints and latex masking fluid to both paint and weather the cold cast-metal, to complete the SWTOR mask of Revan!

Lastly, I used some #000 and #0000 steel wool to buff the forehead, Testors paints and latex masking fluid to both paint and weather the cold cast-metal, to complete the SWTOR mask of Revan!

Since completing the project, I have made various masks, experimenting with different paint schemes. Here are some examples:

That completed the Revan Mask project.

April 2015

In early 2015 I was approached by the Saber Guild, asking me if I would be interested in donating something prop-ish for their raffle at Celebration 7 in Anaheim, the proceeds of which would be donated to the children’s Make-a-Wish foundation. I was very happy to put together a Revan mask for them, shown in the next photo.